Wilt and Blush is the ornate gun sword weapon of the

enigmatic character Adam from the new series RWBY currently being put out by

the folks over at Roosterteeth, I’ve been meaning to get around to this one for

a while so let’s begin.

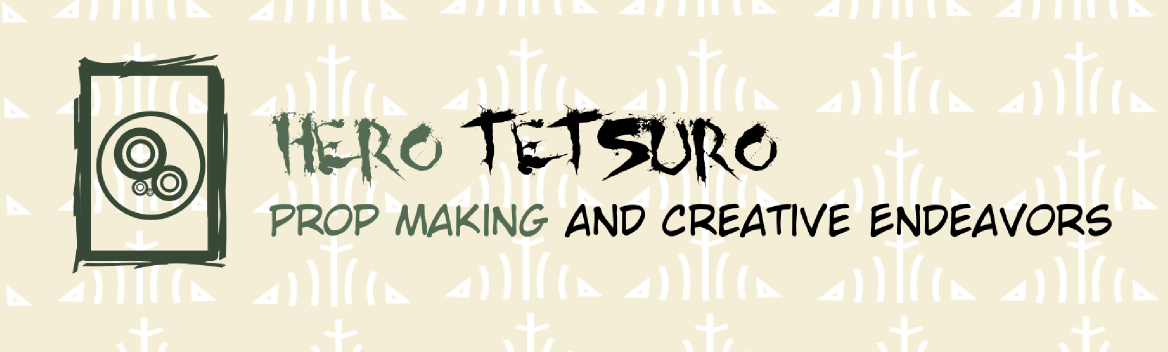

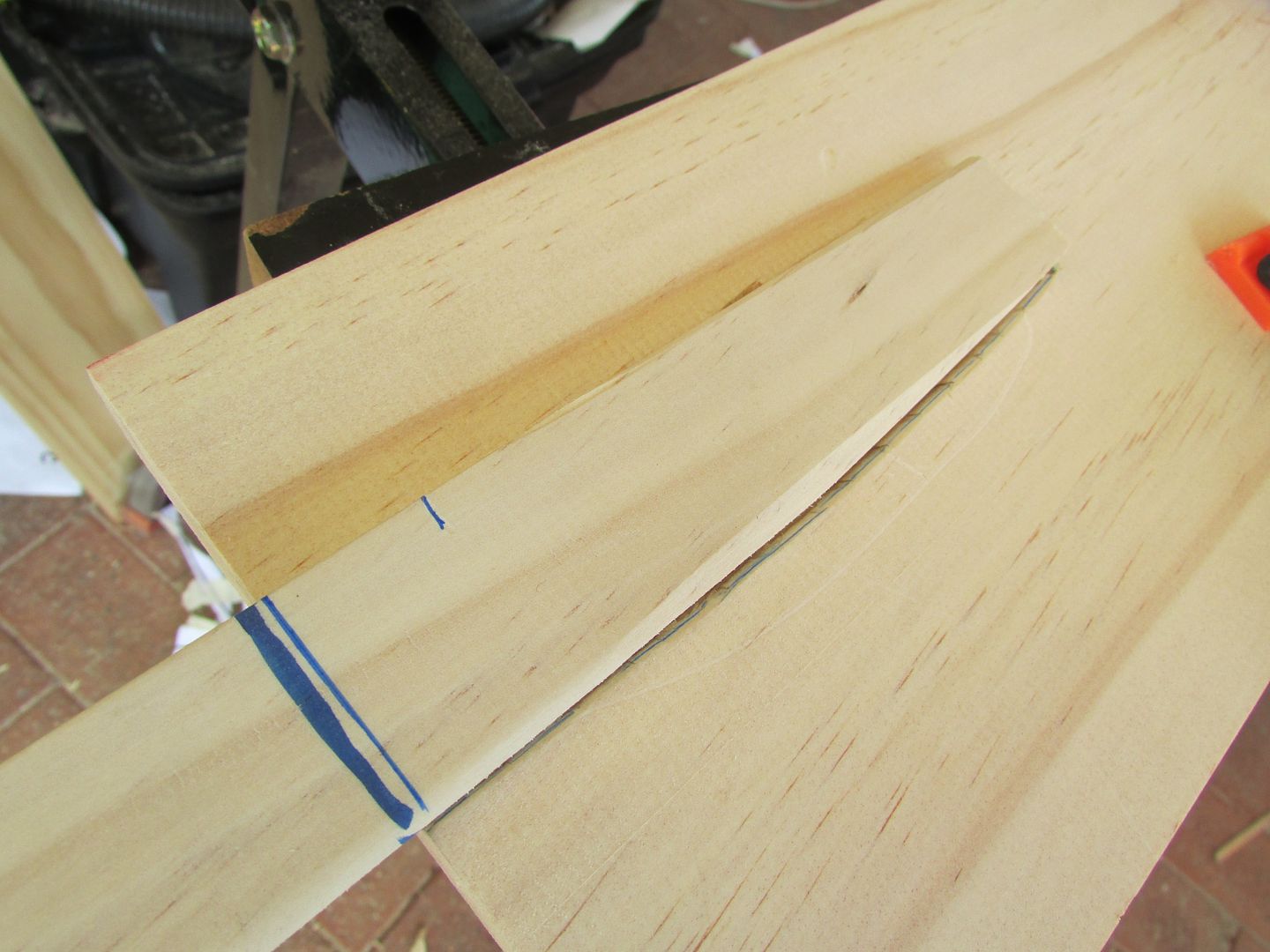

To start off the

katana side of the weapon, I first had to cut out the blade base out of a 12mm

thick plank of pine using a standard jigsaw.

For the bevel of the

blade that was made most with the use of a hand operated belt sander to shape out

most of the "V" shape and sandpaper to clean it up.

Now to make the

handle of the sword itself, firstly I traced out the outline of where the tang

would eventually sit and the rectangular shape of the handle onto another piece

of pine.

It is vitally

important that the grain of the wood is going in the same longitudinal direction

as the overall blade as this mainly helps in the forthcoming chiselling process

but also adds to structural integrity when handling.

With the outlines marked, I could

then begin the process of chiselling, using a standard hammer and a basic

woodworkers chisel set.

Starting from the edge I gradually

tapped first downwards into the plank surface and moved along the outline establishing

the initial depth to chisel out later. Try not to hammer too deep or hard or

you will split the wood, all I can say is take your time and go about it

gradually, until you have a consistent depth all around.

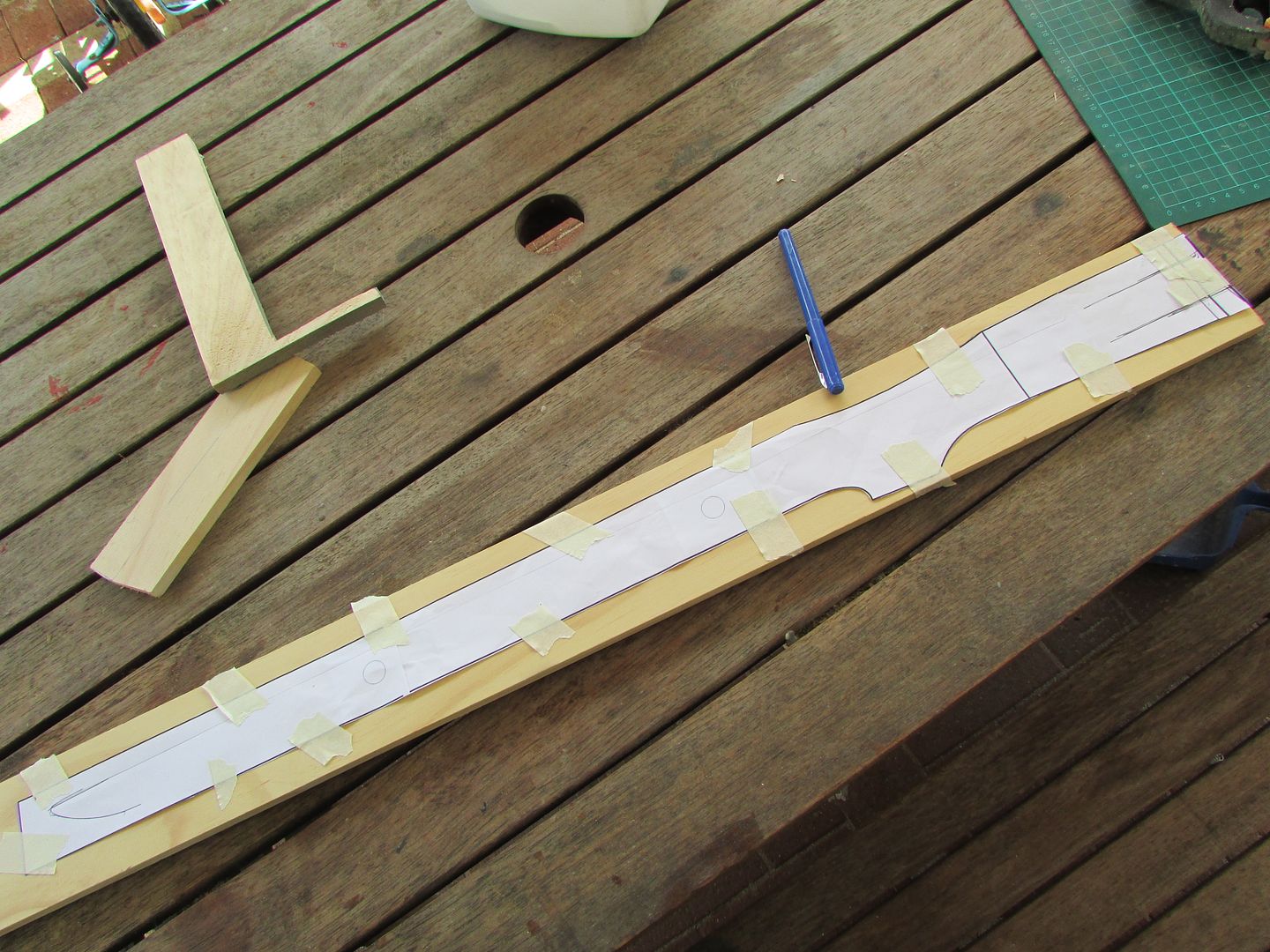

With the initial

depth cut for the entire outline, I then started to chisel away at the surface,

gradually peeling away layer by layer.

I underwent multiple runs of this entire process until the

tang sat snugly in the wooden gap, whilst at the same time making sure that it was

also enveloped to half its thickness.

With one half done I repeated this entire

process again for the opposite corresponding half making sure to mirror all the

parts accordingly.

With both cavities carved out into the pre-cut planks, using

the jigsaw I then cut out along the outer rectangular shape of the handle itself.

The reason I left cutting out to last is because it is much easier to chisel,

in the plank form as opposed to how thin it is now.

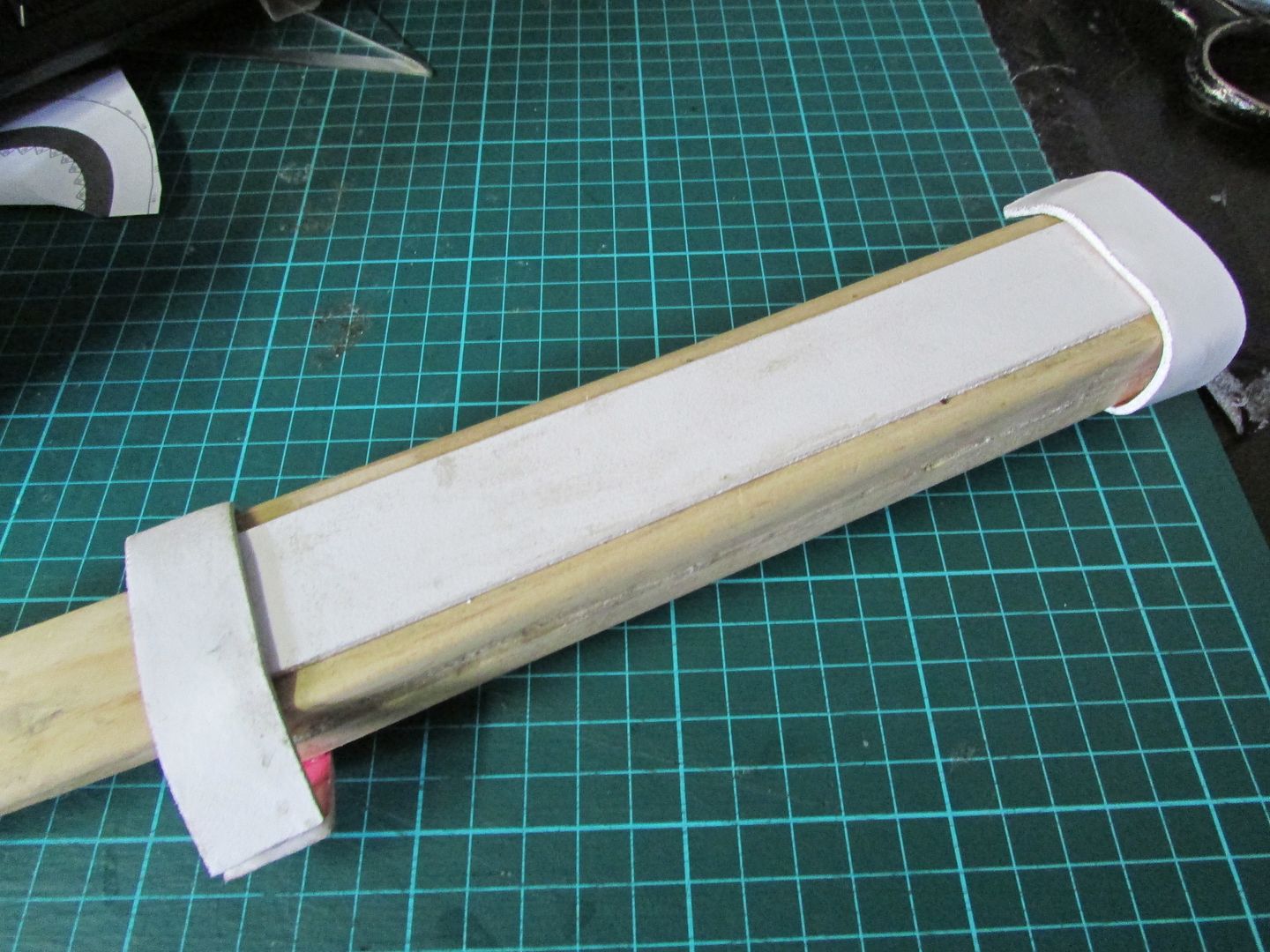

So the two halves were attached together with copious

amounts of wood glue with the aid of clamps, encasing the blade in between.

Starting on detailing on the handle I

first did a quick once over with sandpaper to clean off the sharp edges and

burs.

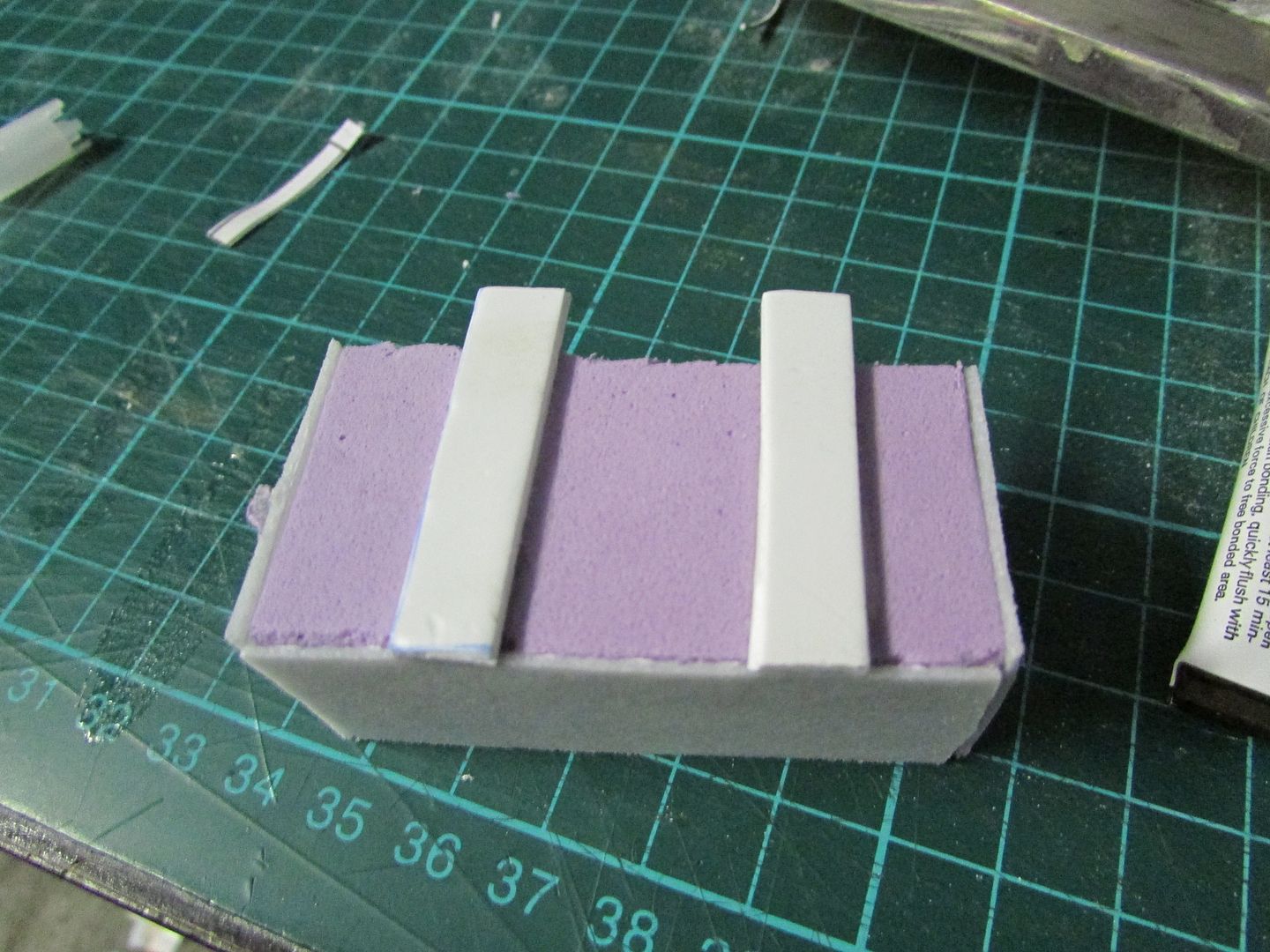

And then resorted to cutting out and attaching of PVC sheeting, some pieces where glued on directly whilst others were first bent with a heat gun then attached, namely the muzzle end and the hand guard.

And then resorted to cutting out and attaching of PVC sheeting, some pieces where glued on directly whilst others were first bent with a heat gun then attached, namely the muzzle end and the hand guard.

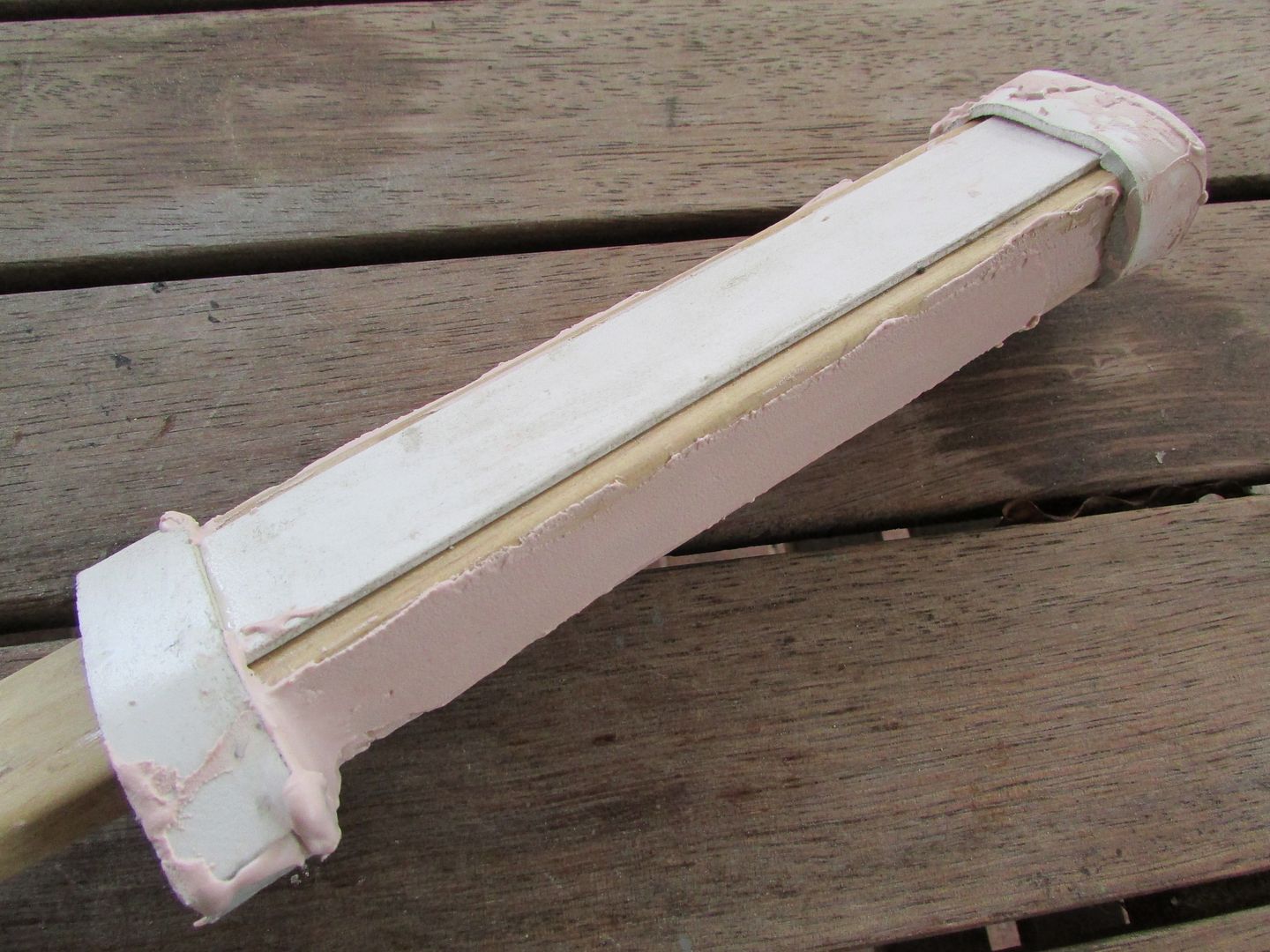

The small gun barrel was cut from a thin PVC pipe and glued

to the wooden base structure, after which I then started sealing up all the

gaps with apoxie sculpt.

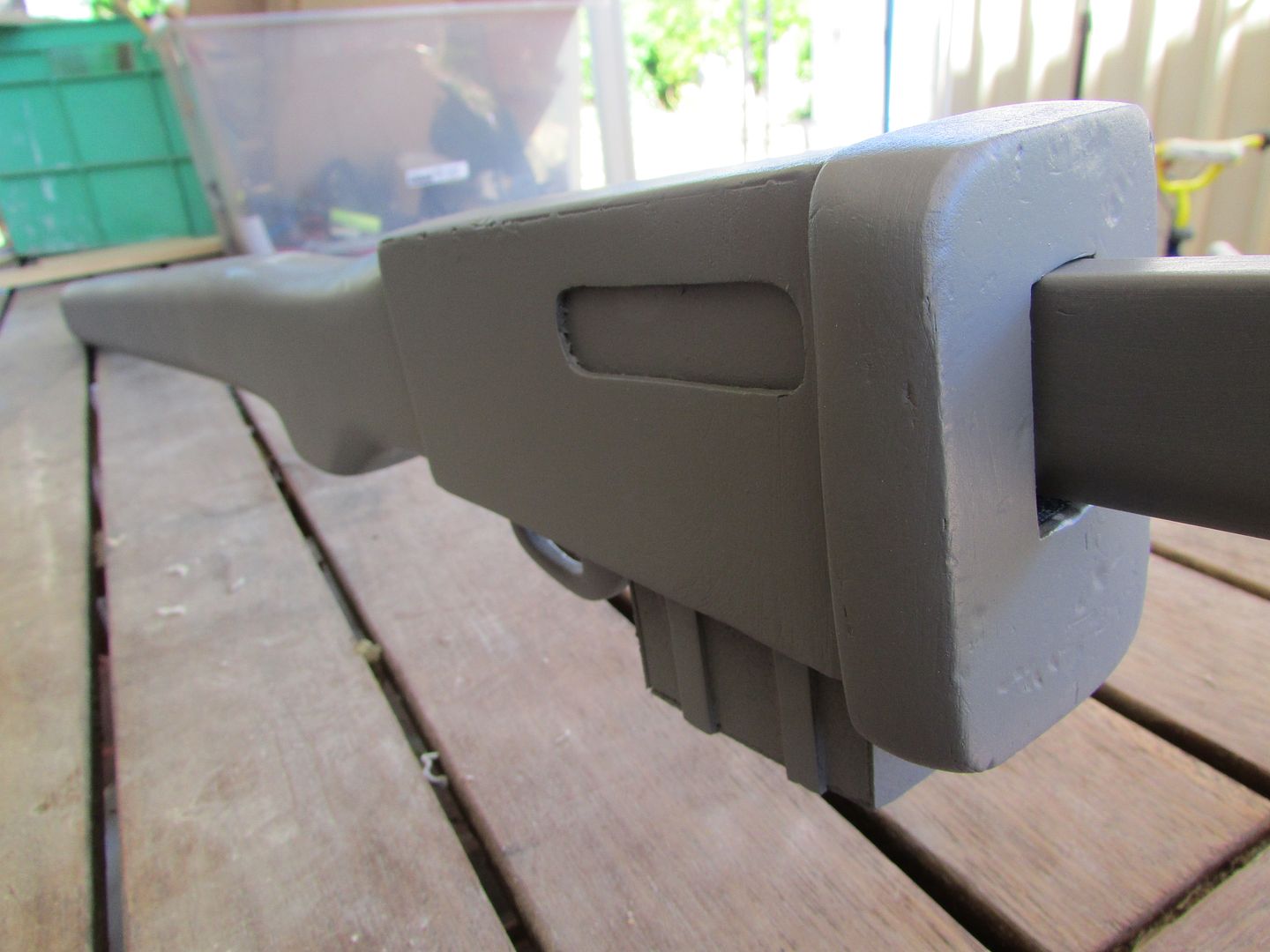

The sealing of the gaps leads into the next major section

where I started with the application of the body filler, to start cleaning up

all the ugly unwanted seams.

A lot of sanding took place as well as a lot of filling. I

used the automotive filler to make up the mass around the muzzle and the hand

guard and then sanded it down to match the contours of the PVC sheeting.

Before a quick intermittent coat of primer to highlight and fill-in

any major defects that I might have missed.

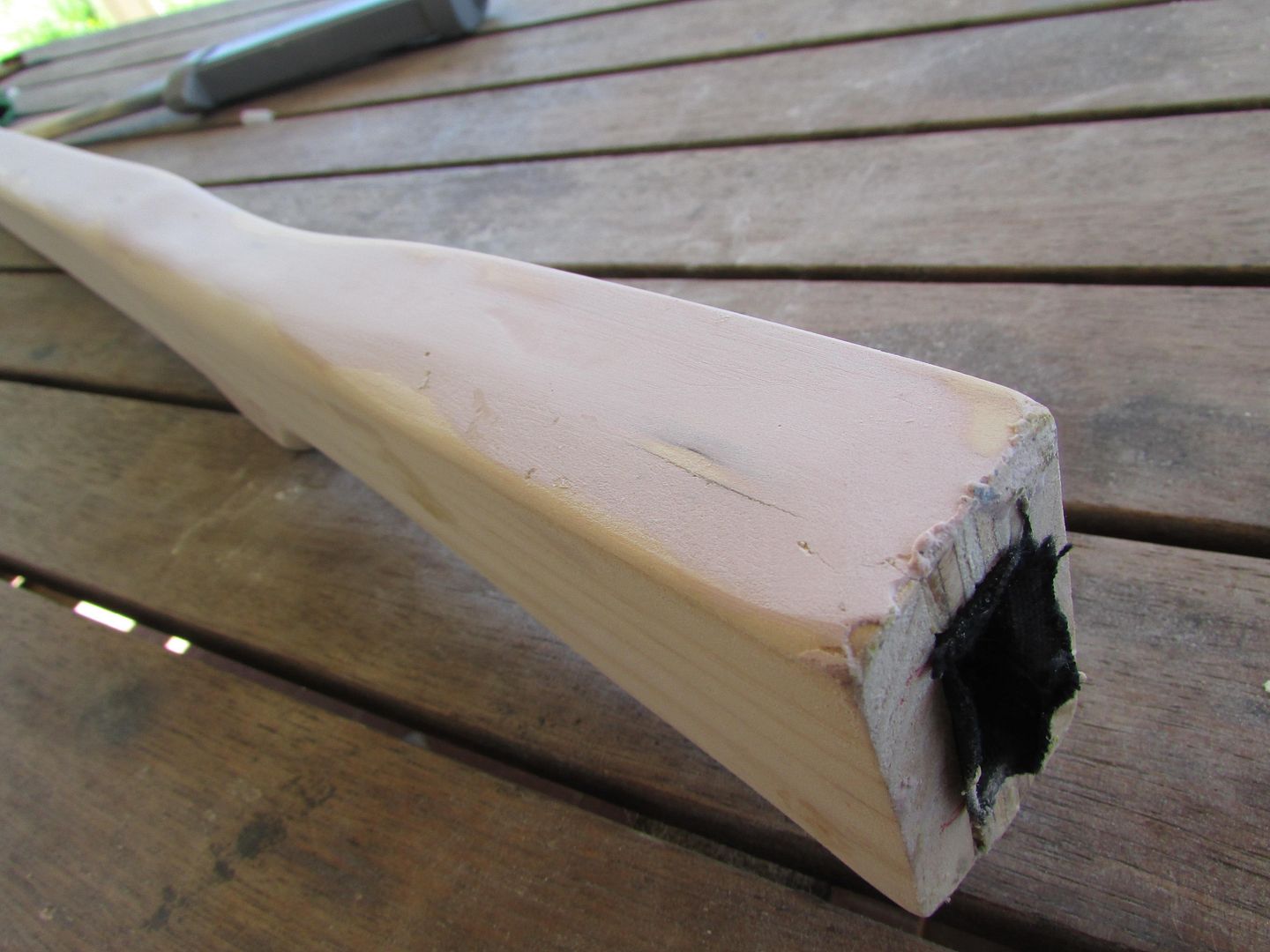

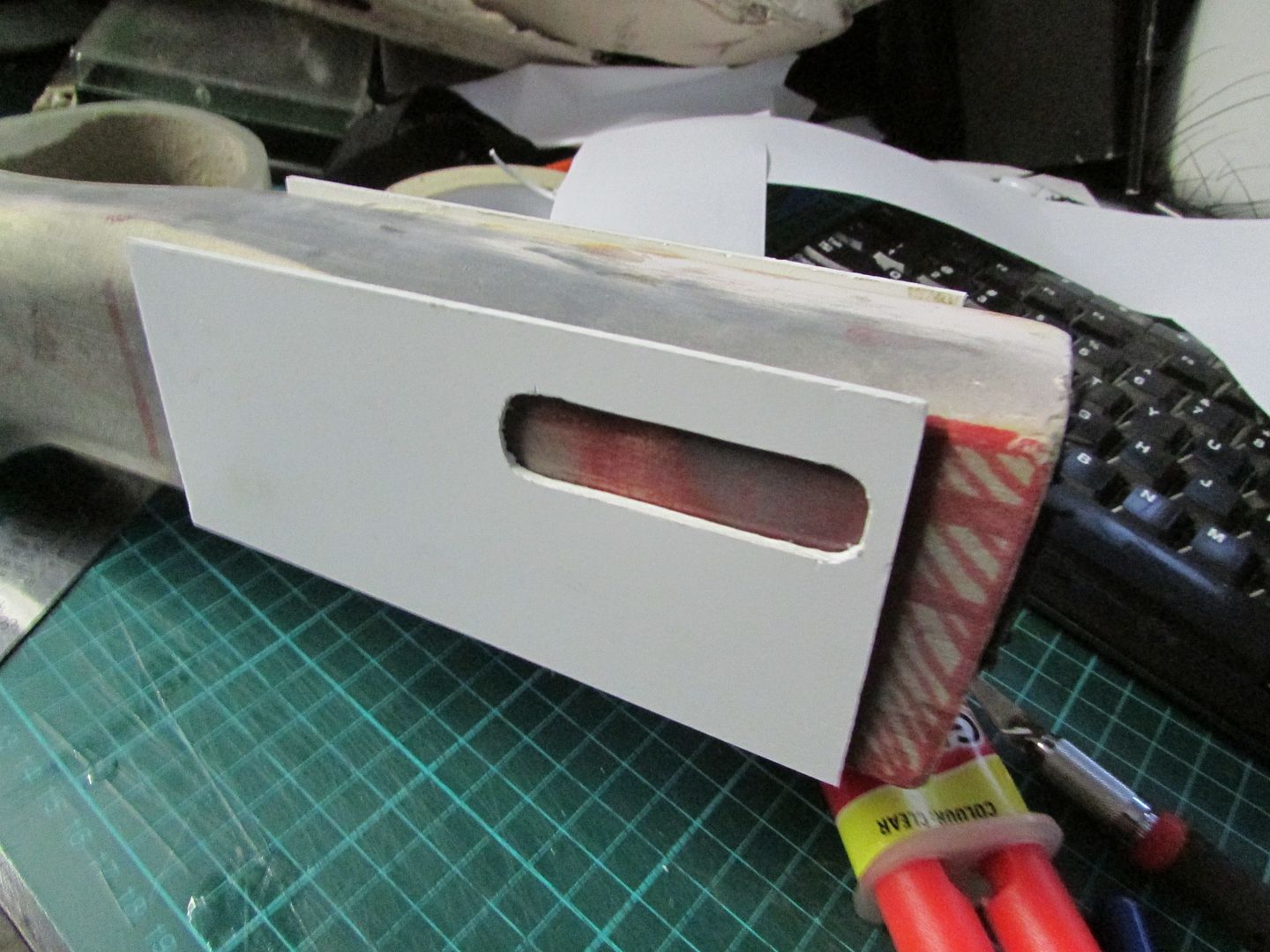

For the scabbard aspect of the prop, that involved first

cutting out two similar side pieces out of pine and then having to make

a sort of box to encase the pre-existing blade.

To make the depth of the “box”, I cut from plywood some thin

strips that matched the contours of the blade and then glued them atop one another

to achieve the thickness required.

These strips were glued to the side face of the scabbard,

creating a similar cavity effect much like the one created by the chiselling earlier.

Some light sanding took place along the inner rims of the

scabbard to make sure the sword fit snug without rattling, but was still able

to slide in an out.

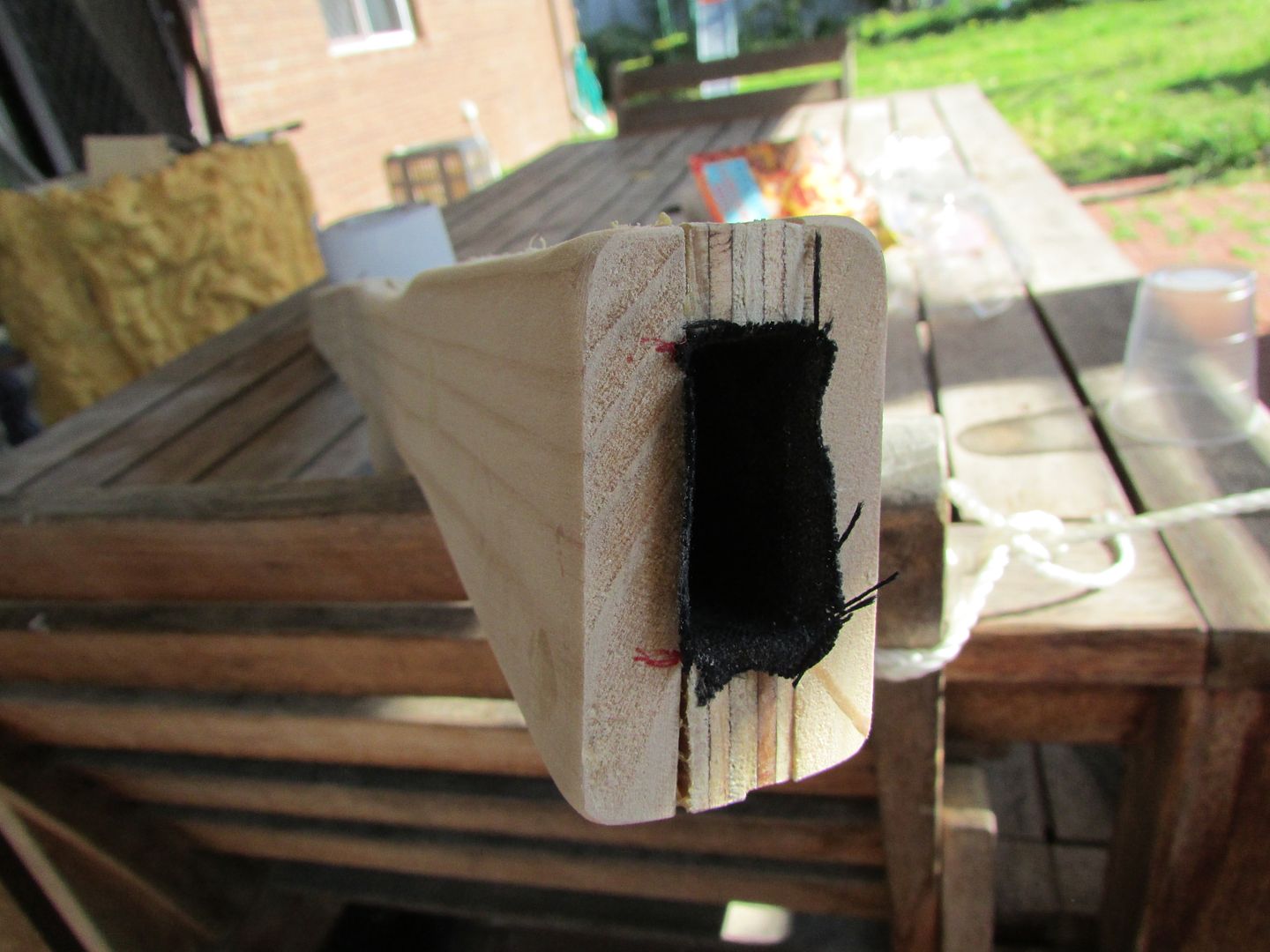

Now to protect the future paintjob I decided to glue in some

black cloth to the inner chamber of the scabbard.

This like I said acts as a

major barrier against paint stripping off as you sheath and unsheath, but also

to a degree prevent the sword from sliding out unnecessarily.

With the cloth glue dry, the two halves were then attached

to one another using powerful clamps and again copious amount of wood glue.

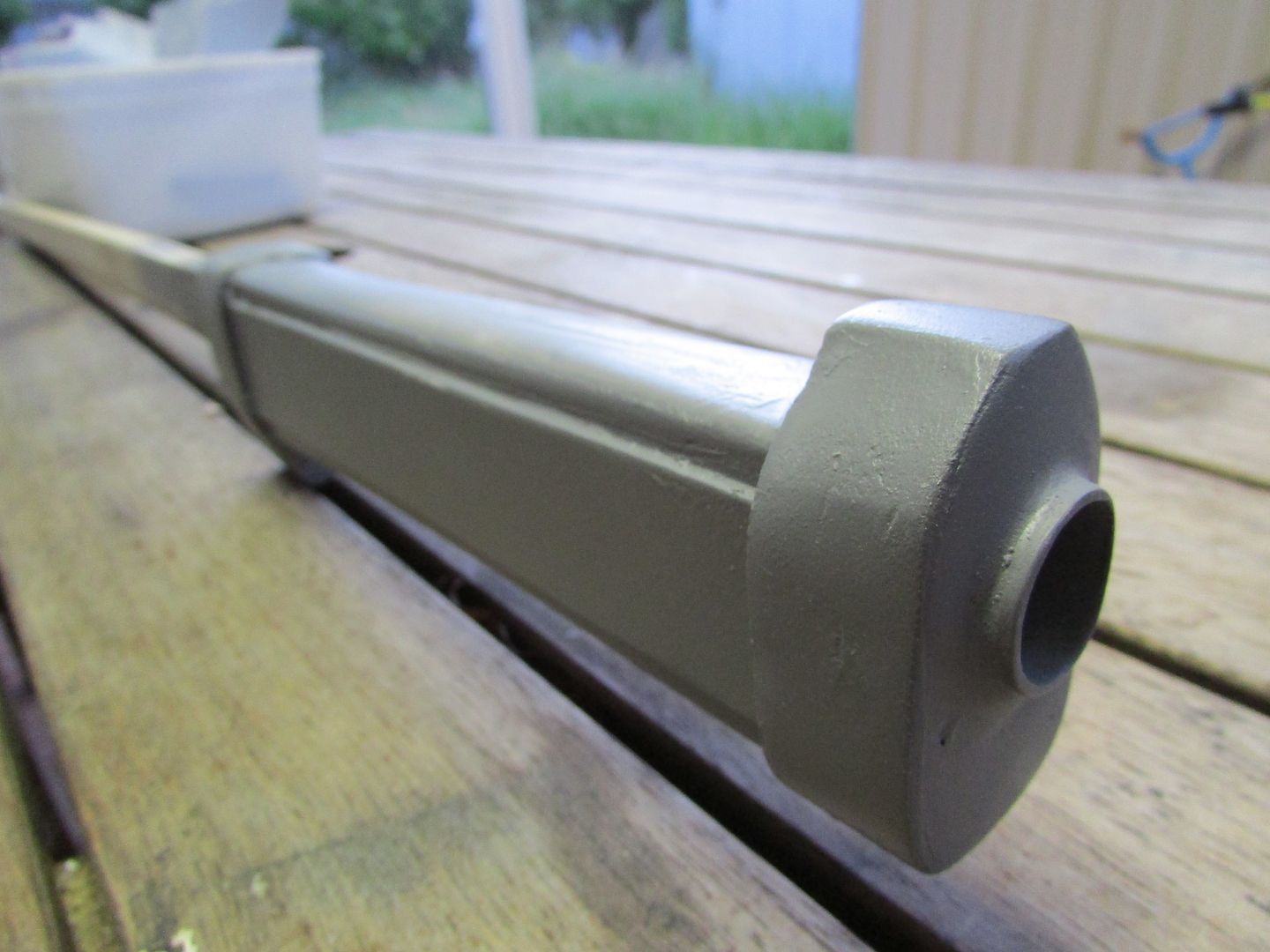

Now that I have this base scabbard, I had to again start cleaning

up all the exposed seams and start shaping the contours of its body using

sandpaper and body filler.

The arduous process of detailing and sanding was done until a

desired ergonomic shape and contour was achieved.

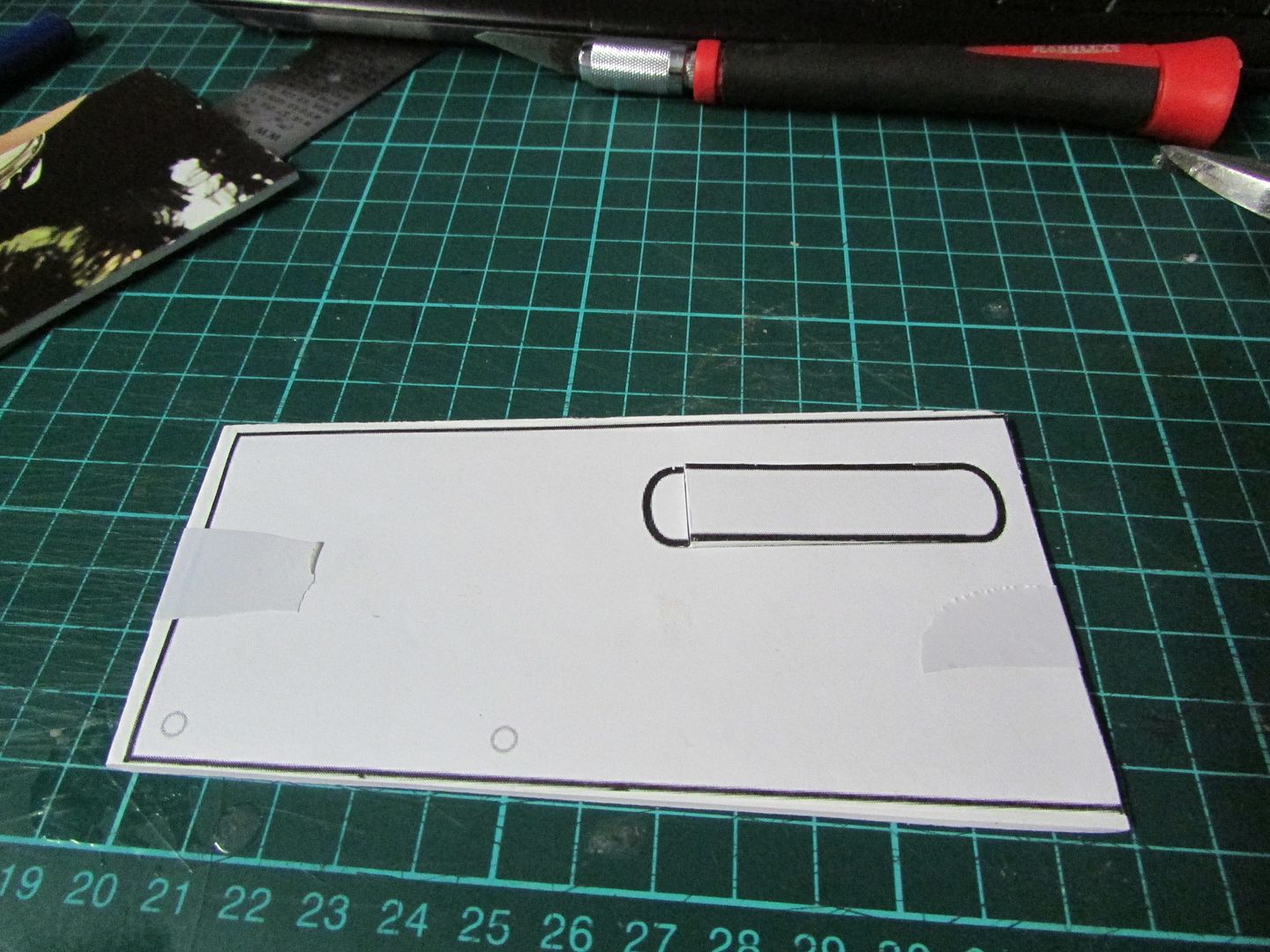

With that process done, more detailing was added in

the form of PVC sheeting to make the receiver and ejection port.

The front face plate was attached to the end face with epoxy

which also doubled as the guide to the sculpting of the shoulder which consited of apoxie sculpt.

Firstly the rough shape was sculpted but was then cleaned up with sanding whe it had cured.

The ammo cartridge made with some EVA foam sheets that were superglued

together and then skinned in wonderflex.

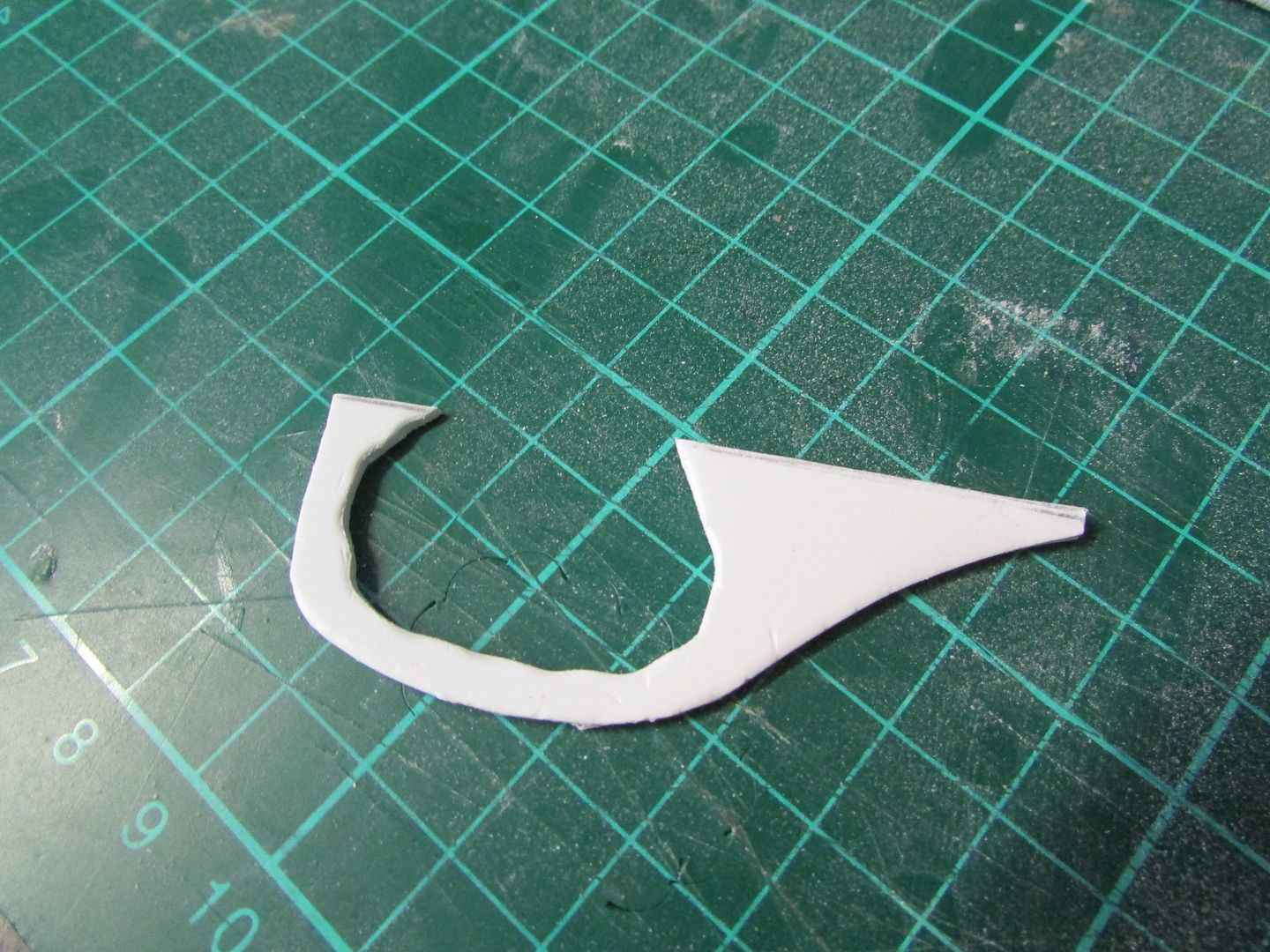

The trigger guard and trigger started out as two dimensional

cut-outs but then had apoxie sculpt moulded around them to get the shape right.

Everything was then attached to the rest of the prop receiver

and then quickly primed to get it all ready for painting.

Paint job involved two coats of grey primer, acrylic paints for most of

the features and a quick once over of dry brushing in to add some duress

and wear. I should also note the insignia was printed out and

transferred with the aid of carbon tracing paper and inked out with

enamel hobby paint.

Thanks for reading.